This is an old revision of the document!

Table of Contents

LED strips!

We love some good LED blinking as much as the next person but after years of LED-soldering we need something cooler to get us excited. Sure there are RGB LEDs and those are fun too but what comes after that? Well, we have the answer: LED Strips! These are flexible circuit boards with full color LEDs soldered on. They take a lot of LED-wiring-drudgery out of decorating a room, car, bicycle, costume, etc. The ones we carry are also waterproof (although not all are).

There are two basic kinds of LED strips, the "analog" kind and "digital" kind. Analog-type strips have all the LEDs connected in parallel and so it acts like one huge tri-color LED; you can set the entire strip to any color you wan, but you can't control the individual LED's colors. They are very very easy to use and fairly inexpensive.

The Digital-type strips work in a different way. They have a chip for each LED, to use the strip you have to send digitally coded data to the chips. However, this means you can control each LED individually! Because of the extra complexity of the chip, they are more expensive.

This tutorial is for the Analog RGB LED strips only!

"Analog" RGB LED strips

Technical specs:

- 10.5mm (0.41") wide, 3mm (0.12") thick, 100mm (3.95") long per segment

- Clear waterproof molded

- 3M adhesive strip on back

- Maximum 12V @ 60mA draw per strip segment

- 3 common-anode RGB LEDs per segment

- LED wavelengths: 630nm/530nm/475nm

- No microcontroller or chip controller ('analog' only!)

- (We're working on getting an English datasheet from the manufacturer!)

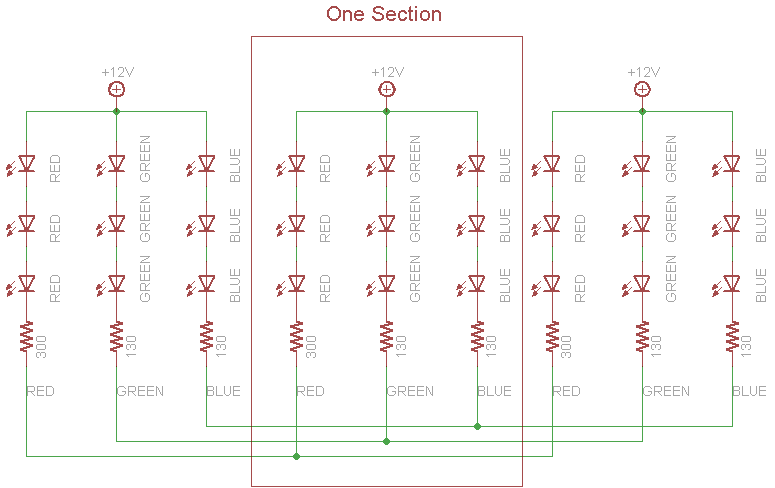

Schematic

Analog type RGB LED strips come on a reel, and are made of 3-LED sections that are 10 cm long. They are easy to cut at the boundary of each section, theres a little cut mark area and some copper tabs you can solder to. Each LED in a section is a '5050' tri-color type, containing a red, green and blue LED. That means that every section really has 9 total LEDs - three red, three green and three blue. The LEDs are arranged in series as shown in the following schematic:

Current draw

Because there are three LEDs in series, you cannot drive these LEDs from a 5V supply. The LED strips say "+12V" on them to mark the anode and that's the maximum voltage we suggest. We've found that if you're ok with them being a little dimmer, even 9VDC works very well.

Each segment draws approximately 20 milliAmperes from a 12V supply, per string of LEDs. So for each segment, there is a maximum 20mA draw from the red LEDs, 20mA draw from the green and 20mA from the blue. If you have the LED strip on full white (all LEDs lit) that would be 60mA per segment.

To find the total maximum current draw per meter, we would multiply 60mA x 10 (ten segments per meter) = 0.6 Amps per meter. Again, that's assuming you would have all the LEDs on at once and that you are powering it from 12V. If you're going to be PWM-fading between colors, maybe 1/2 of that is what you'll be drawing. Still, you do need to have a fairly decent power supply to run this strip, all those LEDs add up!

Wiring

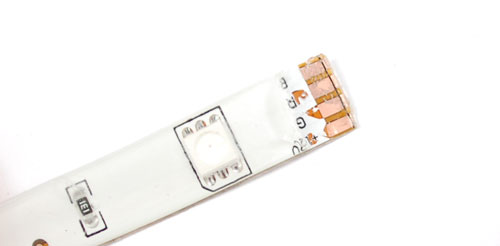

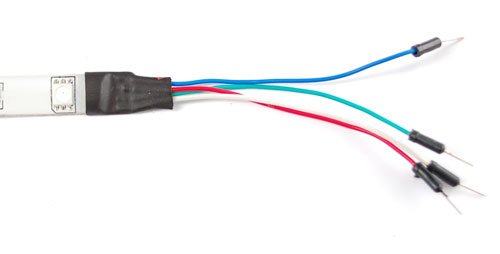

Connecting up to the strip is fairly easy, you'll want to solder four wires to the copper tabs. We'll use white for +12V, then red, green and blue wires for the corresponding LED colors.

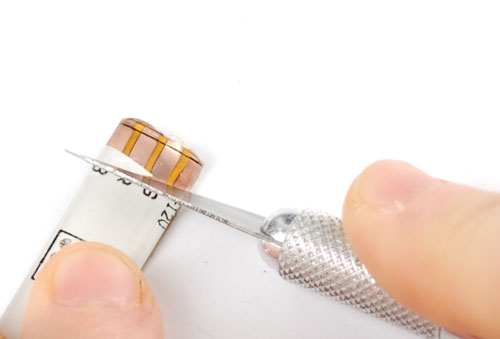

Cut away the waterproof overmolding at one end of the strip. The strips are symmetric so it doesn't matter which end you use

Scrape away the rubber to expose the copper pads

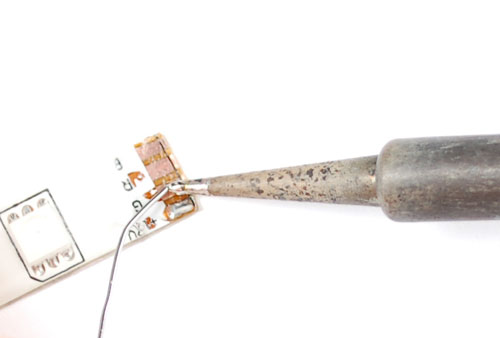

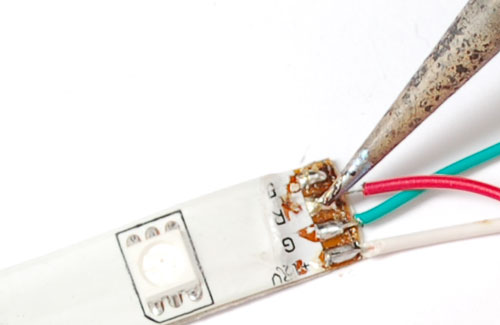

Melt some solder onto the pads to tin them and also burn away any left over rubber

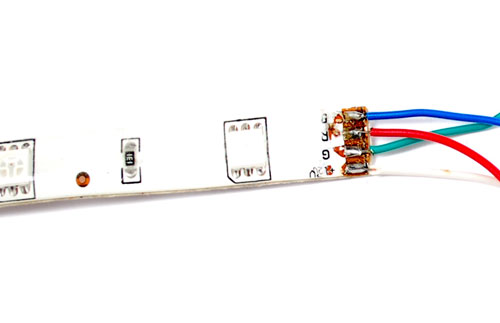

Solder the four wires on. We used stranded wire, which is more flexible and is probably a better choice than solid-core

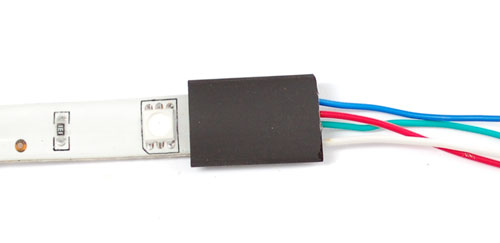

To protect the wires and maintain some waterproofness, you can use heatshrink.