Table of Contents

LED strips!

We love some good LED blinking as much as the next person but after years of LED-soldering we need something cooler to get us excited. Sure there are RGB LEDs and those are fun too but what comes after that? Well, we have the answer: LED Strips! These are flexible circuit boards with full color LEDs soldered on. They take a lot of LED-wiring-drudgery out of decorating a room, car, bicycle, costume, etc. The ones we carry are also waterproof (although not all are).

There are two basic kinds of LED strips, the "analog" kind and "digital" kind. Analog-type strips have all the LEDs connected in parallel and so it acts like one huge tri-color LED; you can set the entire strip to any color you want, but you can't control the individual LED's colors. They are very very easy to use and fairly inexpensive.

The Digital-type strips work in a different way. They have a chip for each LED, to use the strip you have to send digitally coded data to the chips. However, this means you can control each LED individually! Because of the extra complexity of the chip, they are more expensive.

This tutorial is for the Digital RGB LED strips with HL1606 controller chips

"Digital" RGB LED strips

Technical specs:

- 19mm (0.75") wide, 4.5mm (0.18") thick with casing on, 62.5mm (2.45") long per segment

- 32 LEDs per meter

- Removable IP65 waterproof casing

- Maximum 5V @ 120mA draw per strip segment

- 3 common-anode RGB LEDs per segment

- LED wavelengths: 630nm/530nm/475nm

- HL1606 LED controller chip with 'SPI'-like protocol (Chinese Datasheet)

- (We're working on getting an English datasheet from the manufacturer!)

Schematic

Current draw

These LEDs are driven directly from the microchip in the strip, you must provide 5V for both the chip and LED power. Try to keep the supply fairly clean, a BFC (Big Freaking Capacitor) say 1000 uF or greater right at the strip should provide some immunity.

Wiring

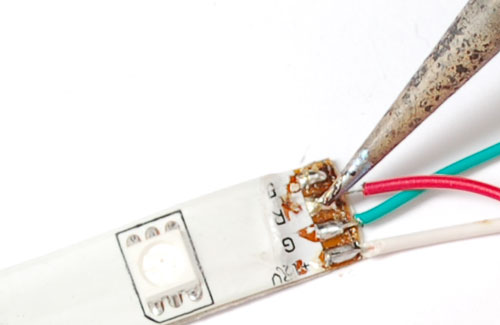

Connecting up to the strip is fairly easy, you'll want to solder four wires to the copper tabs. We'll use white for +12V, then red, green and blue wires for the corresponding LED colors.

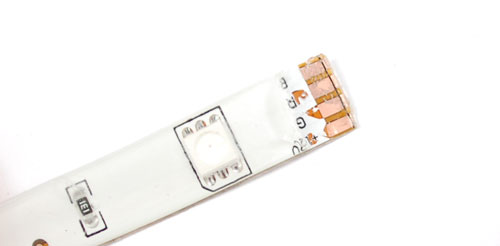

Cut away the waterproof overmolding at one end of the strip. The strips are symmetric so it doesn't matter which end you use

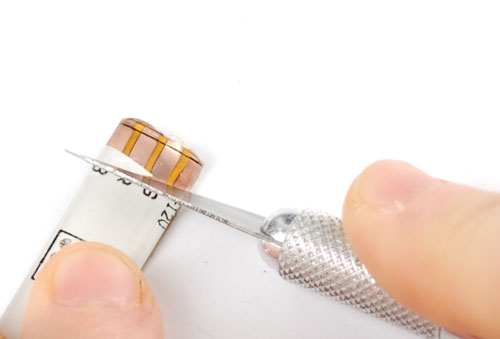

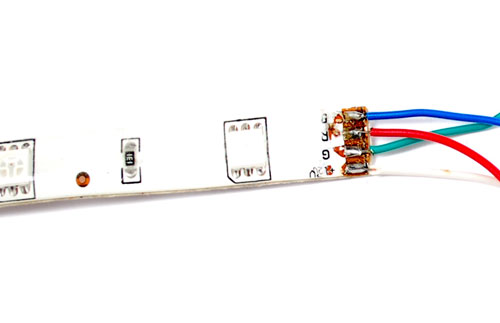

Scrape away the rubber to expose the copper pads

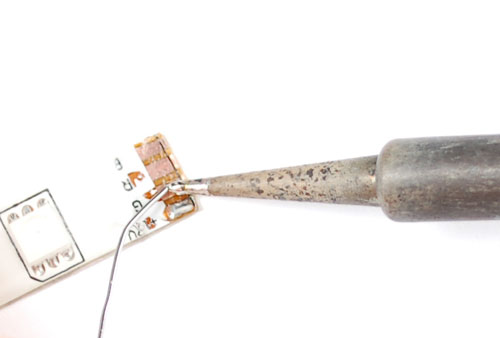

Melt some solder onto the pads to tin them and also burn away any left over rubber

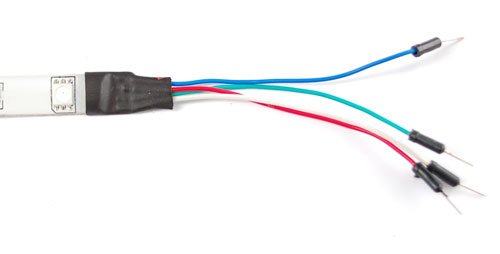

Solder the four wires on. We used stranded wire, which is more flexible and is probably a better choice than solid-core

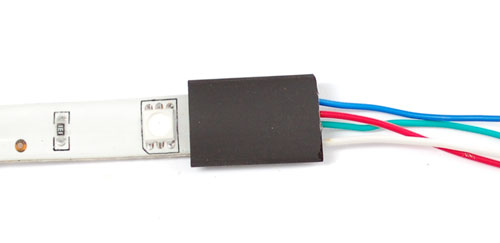

To protect the wires and maintain some waterproofness, you can use heatshrink.